TOPICS

The wear due to natural fiber

Needle Surface Wear

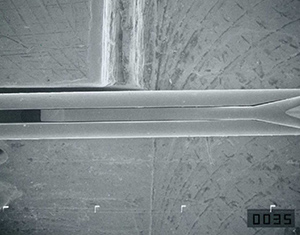

Needle surface before use (magnified 35x)

Needle surface before use (magnified 35x)

Needle surface after open-end yarn is knitted.(magnified 35x)

Needle surface after open-end yarn is knitted.(magnified 35x)

Wear resembling scrapes will appear on the needle surface when yarns containing abrasive particles are used.

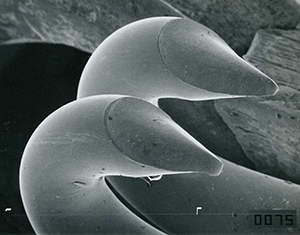

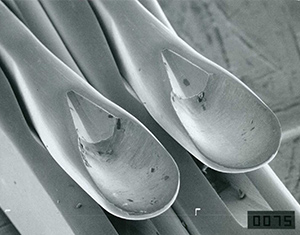

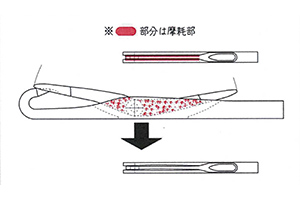

Hook and latch wear

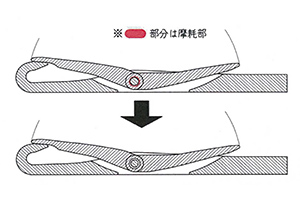

Diagram1 Hook and latch wear

Diagram1 Hook and latch wear

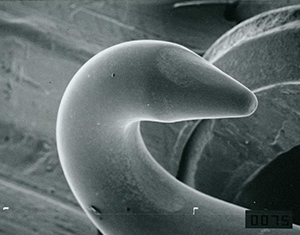

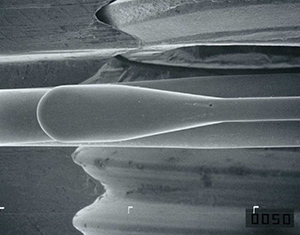

Hook before use x75

Hook before use x75

Worn hook x75

Worn hook x75

Latch spoon before being used x75

Latch spoon before being used x75

Worn latch spoon x75

Worn latch spoon x75

Abrasive particles which adhere and accumulate at the latch spoon area, et cetera will facilitate wear on all areas which make contact when the latch closes.

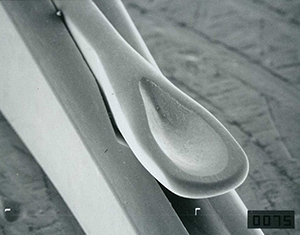

Latch body and slot wear

Diagram2 Latch body and slot wear

Diagram2 Latch body and slot wear

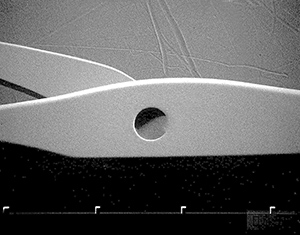

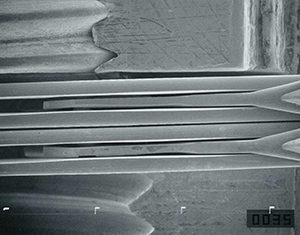

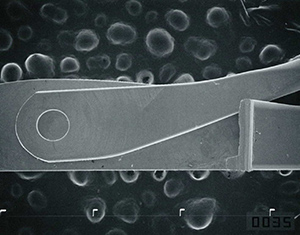

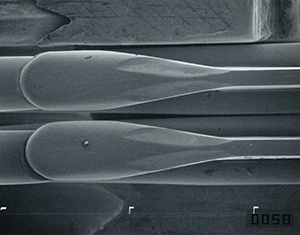

Latch body and slot before use x35

Latch body and slot before use x35

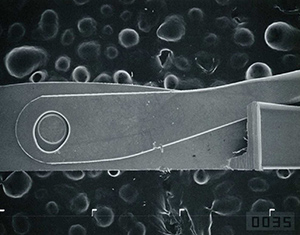

Worn latch body and slot x35

Worn latch body and slot x35

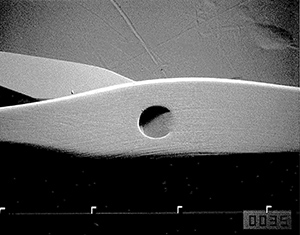

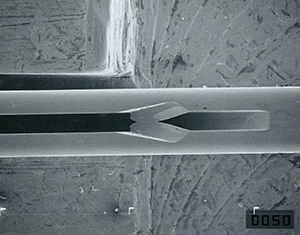

Worn area magnified x75

Worn area magnified x75

Abrasive particles adhere to the latch body and find their way into the latch slot. This facilitates wear on both the body side and slot side during the movement of the latch when it opens and closes.

Latch hole and rivet wears

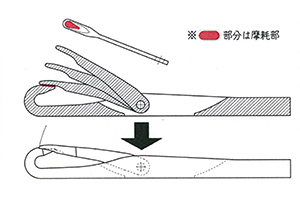

Diagram3 Latch hole and rivet wear

Diagram3 Latch hole and rivet wear

Latch hole and rivet area before use x75

Latch hole and rivet area before use x75

Worn latch hole and rivet area x75

Worn latch hole and rivet area x75

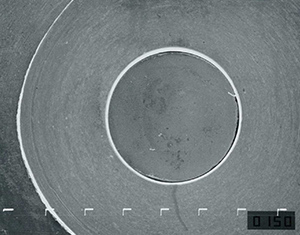

Latch hole and rivet area before use x150

Latch hole and rivet area before use x150

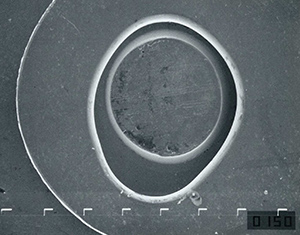

Worn latch hole and rivet area x150

Worn latch hole and rivet area x150

Abrasive particles inside the latch slot will facilitate wear in the area around the revolving axis (latch rivet) of the latch.

Latch back and seat wear

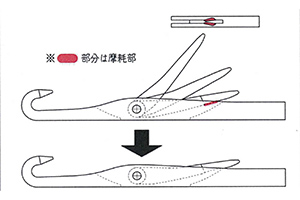

Diagram4 Latch back and seat wear

Diagram4 Latch back and seat wear

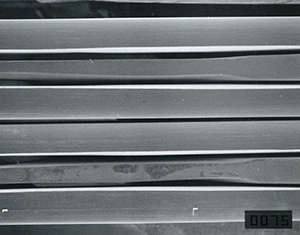

Latch back before use x50

Latch back before use x50

Worn latch back x50

Worn latch back x50

Latch seat before use x50

Latch seat before use x50

Worn latch seat x50

Worn latch seat x50

Abrasive particles which adhere and accumulate at the latch seat area will facilitate wear on all areas which make contact when the latch opens.

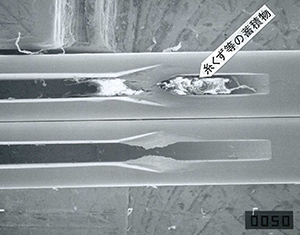

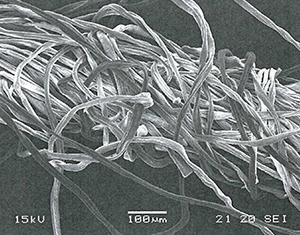

Abrasive fibers (impurities) found in natural fibers

Abrasive particles (impurities) have a tendency to adhere to natural fibers found in open-end yarn, et cetera. Using these sorts of yarns will bring about wear in various areas on the needle

The surface of open-end yarn x150

The surface of open-end yarn x150

Magnified x500

Magnified x500

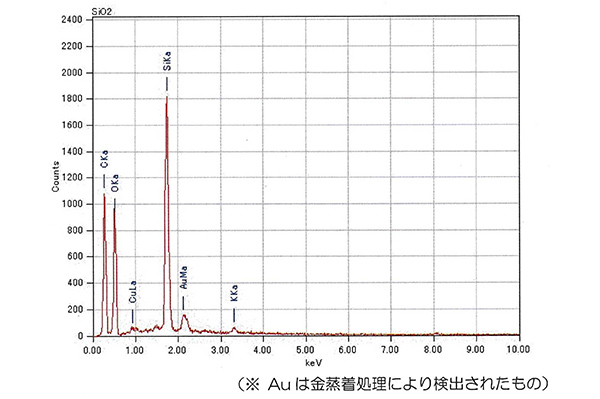

【Data1 Analysis of abrasive objects adhered to yarn】

【Data1 Analysis of abrasive objects adhered to yarn】

Based on the results of the analysis, the object adhered to the yarn in figures 18 and 19 is thought to be SiO2 (silica).

Analyzing objects adhered to yarn in this way can show how these objects were likely on the raw cotton from the time it was harvested. It is often the case that these objects are found to contain highly abrasive impurities.

contact

Please feel free to contact us

with any questions or inquiries

regarding our products.