TOPICS

Needle trouble and causes

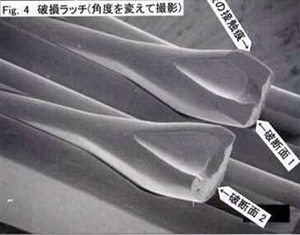

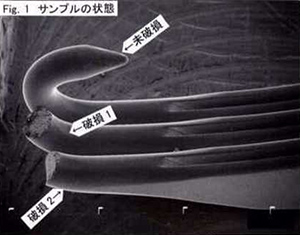

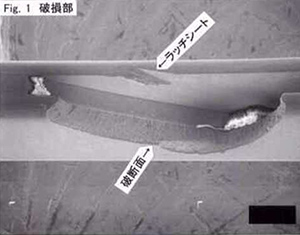

Latch breakage

Causes

High-speed, tight-stitch, contact with Y/C, rust, wear, etc.

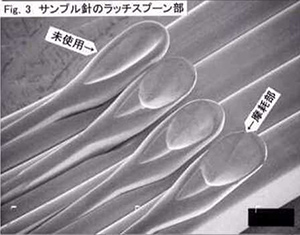

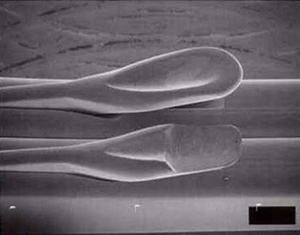

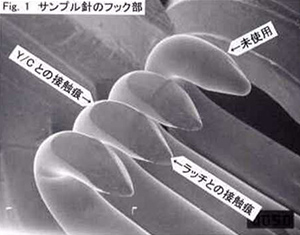

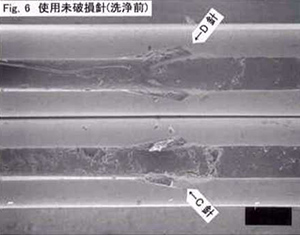

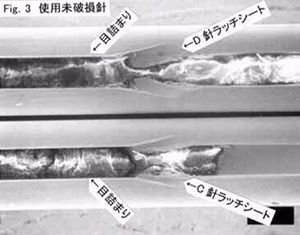

Latch wear

Causes

Poor quality yarn, oil-shortage, high-yarn tension,contact with Y/C, etc.

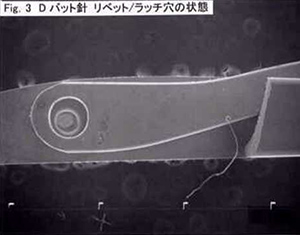

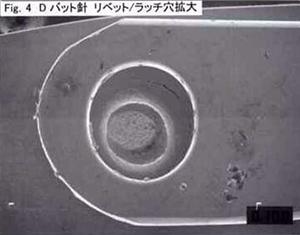

Latch rivet wear / loose latch

Causes

Poor quality yarn, oil-shortage, high-yarn tension, etc.

Hook breakage

Causes

Shock wave from high-speed knitting, excessive yarn tension, lint accumulation or slabs, fabric load up, etc.

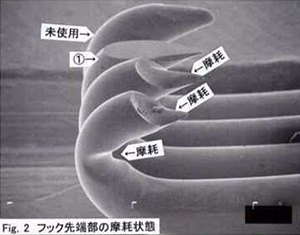

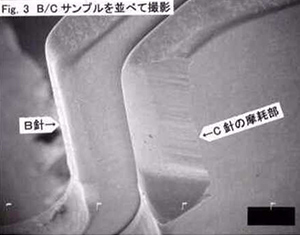

Hook wear

Causes

Poor quality yarn, oil-shortage, high yarn-tension, contact with Y/C, etc.

Lint accumulation

Causes

Poor quality yarn, insufficient-air-blowing, excessive wax, insufficient maintenance, etc.

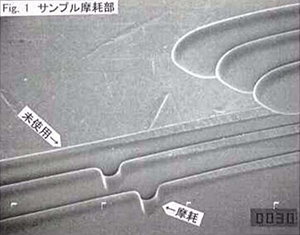

Butt wear

Causes

Oil-shortage, bad (abrasive) cam-surface, high-yarn tension, poor quality yarn, insufficient maintenance, etc.

Butt Breakage

Causes

Oil-shortage, bad (abrasive) cam-surface, high-yarn tension, poor quality yarn, insufficient maintenance, etc.

Cheek Chipping

Causes

Inappropriate latch seat, etc.

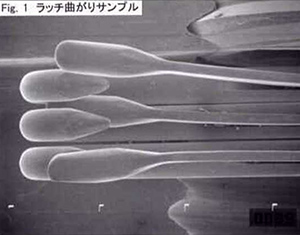

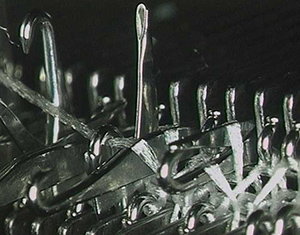

Latch bending, Latch going into hook

Causes

Operator errors (after press-off, etc), contact with Y/C, etc.

Filamentation

Causes

Burr on latch slot edge, insufficient trapping clearance, etc.

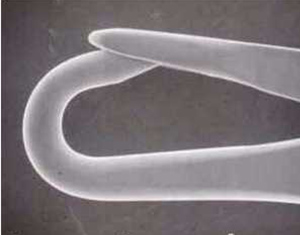

Opened Hook

Causes

Inappropriate yarn-count, small hook (larger hook needed), insufficient material strength, etc.

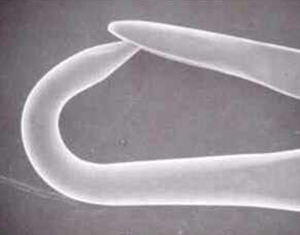

Swan neck

Causes

Excessive take-up tension

Oil lines

Causes

Excessive oil, needle bending

Needle lines

Causes

Yarn movement not smooth, poor needle quality, wear, lint accumulation, etc.

Sinker Wear

Causes

Poor quality yarn, excessive yarn tension, etc.

contact

Please feel free to contact us

with any questions or inquiries

regarding our products.